![]() Thermal Shock Testing

Thermal Shock Testing

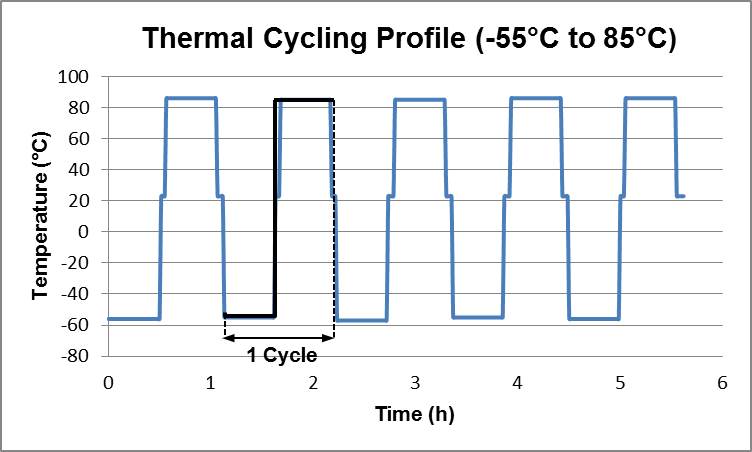

Electromechanical and electronic components used in aerospace, avionics, and military applications must not only survive but reliably operated in environments that experience extreme and sudden changes in temperature. A component's ability to tolerate and reliably perform in alternating extremes of low and high temperatures is paramount to the safety and success of conventional to mission-critical operations. OTS provides thermal shock testing in accordance with the industry standard temperature range of -40°C to +85°C to a full military standard temperature range of -55°C to +125°C.

Thermal Test System

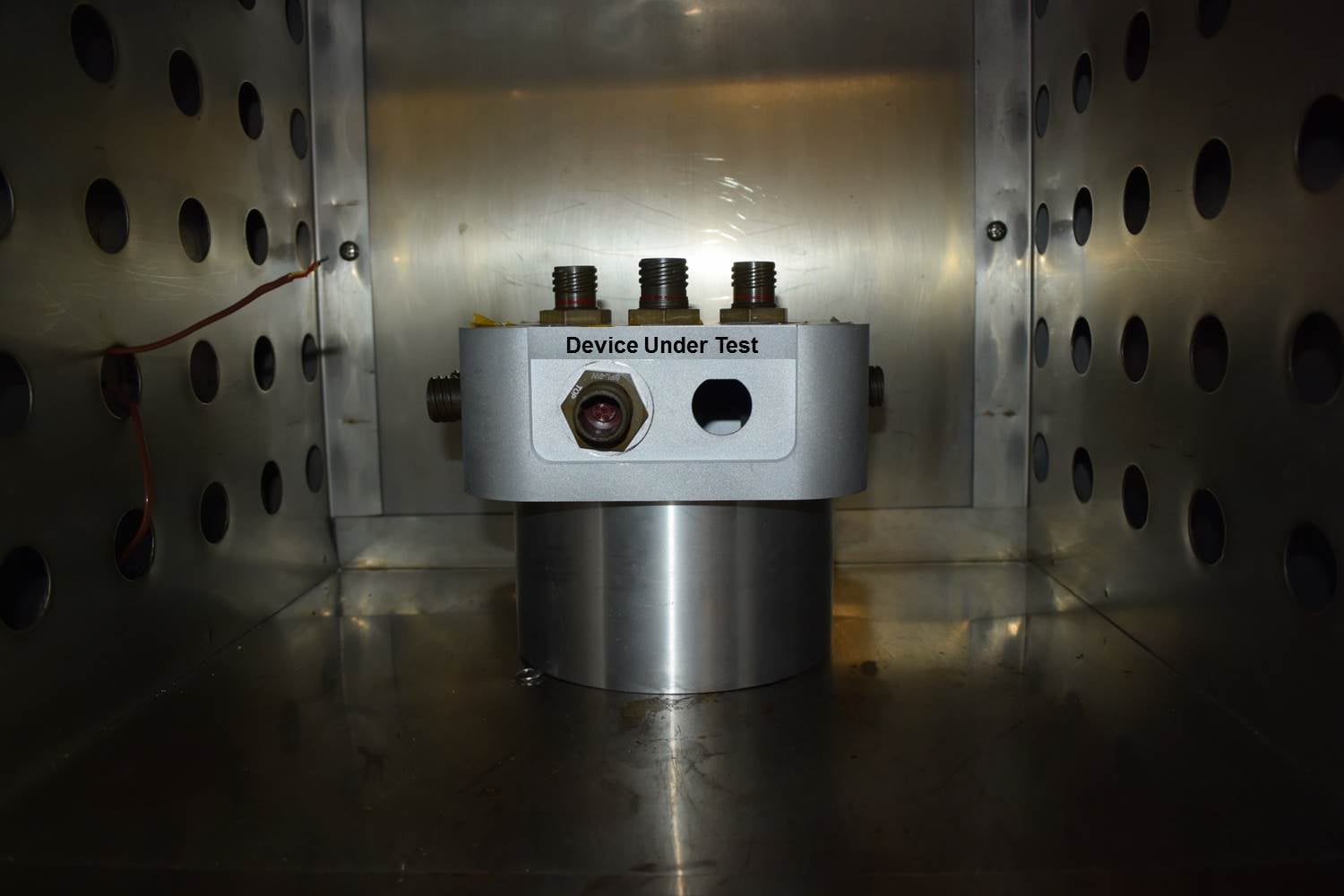

OTS utilizes two specially equipped bench-top environmental chambers that provide temperature cycling and conditioning options to validate the reliability of the most sophisticated electronics, sensors and component parts in extreme temperature conditions. Our two chamber (air-to-air) thermal cycling system allows for a less than one minute transfer time between hot and cold chambers. For slower cycling rates, our one chamber system has a temperature range from -70°C to +200°C with a temperature cycling rate from 5 to 20°C per minute. All cycling and conditioning tests are programmable with our highly accurate temperature controller giving customers the testing flexibility and accuracy needed for multiple ramp and target set points.

System Features

- Access Port

- Specimen Size up to 0.9

- Temperature Range: -70°C to +200°C

- Temperature Change Rates: 5°C to 20° C per min.

- Highly Accurate Temp. Control: ±0.1% Linear Input

Testing to the Standard

OTS will work with you to create the most appropriate testing protocol designed to validate your component's survivability in the harshest of thermal environments. OTS is here to assist and support you in developing a highly robust product that meets or exceeds military and industry standards.

OTS offers several testing specifications designed to validate your components as the most reliable in the industry:

ANSI/EIA-364-32G MIL-STD 810, Method 501

JESD22-A104D MIL-STD 810, Method 502

MIL-STD 202, Method 107 MIL-STD 810, Method 503

MIL-STD 750, Method 1051 MIL-STD 883, Method 1010